Warehouse racking will be the central part in economical storage administration, making it possible for businesses to optimize Place, improve accessibility, and improve productivity inside their amenities. With numerous racking techniques accessible, warehouses can efficiently organize and retailer resources In accordance with their unique needs, from smaller points to bulk items. Picking the proper racking system not only maximizes storage capability but Also makes sure worker basic safety and smooth operations.

Types of Warehouse Racking

Many varieties of racking methods is often found in warehouses, Every single with unique rewards customized to different storage necessities:

Selective Pallet Racking: Here is the most frequent racking method, offering direct obtain to each pallet. It’s remarkably adaptable, so that it is perfect for warehouses utilizing a superior turnover of varied items. Selective racking maximizes accessibility, although it may not be as Room-effective as other systems.

Push-In/Drive-By Racking: Made for high-density storage, generate-in racking allows forklifts for getting in the racking technique to carry and retrieve pallets. It’s perfect for storing significant volumes of comparable things in a last-in, first-out (LIFO) program. Travel-by way of racking, on the other hand, follows a first-in, first-out (FIFO) program and it is superb for stock rotation.

Cantilever Racking: Best suited to storing extensive, cumbersome products like pipes, lumber, and metal rods, cantilever racks offer open fronts that simplify loading and unloading. They are frequently used in construction and producing services the place long materials have to have versatile storage.

Thrust Back again Racking: This method operates within the compilation of nested carts that roll alongside rails, letting pallets to be stored two to six deep. It’s a competent, higher-density Alternative for things which don’t require quick retrieval, running about a LIFO program.

Mezzanine Racking: By incorporating a 2nd along with 3rd level which has a warehouse, mezzanine racking efficiently doubles or triples obtainable flooring location without having growing the making by itself. This technique is perfect for maximizing vertical Area.

Advantages of Effective Warehouse Racking

An effective racking procedure substantially improves warehouse operations by optimizing Area utilization, improving entry, and minimizing retrieval situations. This warehouse racking Sunshine Coast leads to raised stock management, as goods is very easy to get to and organized, which minimizes labor prices and boosts productiveness.

Racking methods also market basic safety by supplying structured and steady storage. Properly created racks reduce the probability of accidents, guaranteeing a secure setting for both personnel and stock. In addition, nicely-maintained racking methods decrease harm to saved merchandise, boosting stock lifespan.

Picking out the Proper Racking Method

Selecting the correct racking system is determined by components like obtainable House, inventory style, turnover charge, and budget. A thorough assessment of storage requires and operational movement works very well for choosing a racking process that supports streamlined workflows and maximizes warehouse efficiency. Effectively executed, warehouse racking can be an financial investment that takes treatment of in Place personal savings, safety, and extended-expression productivity.

Ross Bagley Then & Now!

Ross Bagley Then & Now! Ashley Johnson Then & Now!

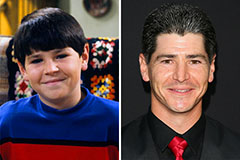

Ashley Johnson Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Seth Green Then & Now!

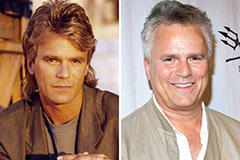

Seth Green Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!